what is a self tapping screw

A self-tapping screw taps its own hole while being driven into the material, especially metal, wood, and plastic. Self-tapping screws have sharp points and threads that cut into the material like knives, eliminating the need for a pilot hole.

They are commonly used in situations where traditional screws would require pre-drilled holes, making them versatile fasteners for various applications. Self-tapping screws are known by different names like metal screws, sheet metal screws, tapping screws, or tapper screws, depending on the industry or region.

Their ability to create their own threads sets them apart from traditional screws, offering efficiency and convenience in fastening tasks.

The Basics Of Self Tapping Screws

A self-tapping screw is designed to create its own hole while being fastened into the material. It features sharp threads that act like knives, ideal for use in metal, wood, or plastic. This type of screw eliminates the need for a separate pilot hole, making it convenient for various applications.

Defining Self Tapping Screws

A self-tapping screw is a type of screw that is designed to create its own hole as it is driven into the material. Unlike traditional screws, self-tapping screws do not require a pilot hole to be drilled beforehand. The screw’s sharp point and threads act like knives, cutting into the material and creating a thread as it is screwed in.Unique Characteristics

Self-tapping screws have unique characteristics that make them stand out from traditional screws. These screws have a sharp point that helps them drill into the material without the need for a pilot hole. They also have threads that are sharp and can easily cut into the material, creating a thread in the process. Self-tapping screws are commonly used in sheet metal, plastic, and wood materials. They are also used in applications where the screw needs to be easily removable or replaced. These screws are available in a variety of sizes, shapes, and materials, making them suitable for a wide range of applications. In conclusion, self-tapping screws are a versatile type of screw that can be used in a variety of applications. They are designed to create their own hole as they are screwed in, making them a popular choice for materials such as sheet metal, plastic, and wood. Their unique characteristics make them an essential component in many industries, from construction to electronics.Types Of Self Tapping Screws

Thread-cutting Screws

A self-tapping screw that cuts a thread into the material as it is driven in.

Thread-forming Screws

A self-tapping screw that forms a thread in the material without removing it.

Self Tapping Vs. Traditional Screws

When it comes to fastening materials, understanding the differences between self-tapping and traditional screws is crucial. Self-tapping screws are designed to create their own hole as they are driven into the material, eliminating the need for a pilot hole. On the other hand, traditional screws require a pre-drilled pilot hole for installation. Let’s delve into the design differences and functional distinctions of these two types of screws.

Design Differences

Self-tapping screws are engineered with a sharp point and threads that act as cutting edges, allowing them to tap their own hole during installation. In contrast, traditional screws have a blunt tip and require a pre-drilled pilot hole to facilitate installation.

Functional Distinctions

Self-tapping screws are predominantly used in metal applications, thanks to their ability to create threads in metal materials. Moreover, they can also be utilized for drilling into wood and plastic. Traditional screws, on the other hand, necessitate the use of a drill or screwdriver to create a pilot hole before installation. This fundamental difference makes self-tapping screws more versatile and efficient in various applications.

Credit: www.ejot.com

Practical Applications

A self-tapping screw is a versatile fastener with practical applications in various materials such as metal, wood, and plastics. Let’s explore the specific uses of self-tapping screws in different applications.

In Metal Works

When it comes to metal works, self-tapping screws play a crucial role. These screws are commonly used in metal fabrication, automotive assembly, and construction projects. The sharp threads of self-tapping screws enable them to create their own mating threads in metal surfaces, eliminating the need for pre-drilling pilot holes.

With Wood And Plastics

Self-tapping screws are also highly effective in wood and plastic applications. In woodworking, these screws can be used to join wooden components without the need for tapping or pre-drilling. Similarly, in plastic assemblies, self-tapping screws provide a convenient and secure fastening solution.

Installation Techniques

A self-tapping screw is a versatile fastener that can tap its own hole as it is driven into the material. When it comes to installation, there are several techniques to consider to ensure the effectiveness of self-tapping screws.

Drilling Pilot Holes

Drilling pilot holes is a crucial step when using self-tapping screws, especially in harder materials such as metal. It involves creating a small guide hole using a drill bit before driving the screw into the material. This allows the screw to easily cut into the material and reduces the risk of damage or breakage.

Using A Drill For Self Tapping Screws

Using a drill for self-tapping screws is a common practice to ensure precision and efficiency. It is essential to select the appropriate drill bit size that matches the diameter of the screw to create pilot holes. Additionally, using a drill with adjustable torque settings can prevent overtightening and damage to the material.

Advantages Of Self Tapping Screws

A self-tapping screw is a type of screw that can tap its own hole as it is driven into the material. It is specifically designed to produce a thread in relatively soft materials or sheet materials, excluding wood. Here are the advantages of using self-tapping screws:

Time Efficiency

Self-tapping screws are time-efficient as they eliminate the need for pre-drilling pilot holes. This can significantly reduce the overall assembly time, making them a preferred choice for projects that require fast and efficient installation.

Versatility

These screws offer versatility in their application. They can be used in various materials such as metal, wood, and plastic, making them suitable for a wide range of projects. This versatility simplifies the selection process and reduces the need for multiple types of screws for different materials.

Potential Drawbacks

One potential drawback of using self-tapping screws is that they require drilling a pilot hole, which can lead to thermal damage and potential issues like hardware loosening or nonunion.

Thermal Damage Risks

Drilling pilot holes for self-tapping screws can cause thermal damage, risking complications such as infection.

Hardware Loosening Concerns

Self-tapping screws may lead to hardware loosening and potential nonunion issues over time.

Credit: bdnfasteners.com

Choosing The Right Screw For Your Project

A self-tapping screw is a unique type that creates its own hole while being driven into the material. These screws are ideal for softer materials and sheet metals, featuring sharp threads that cut into the surface effectively.

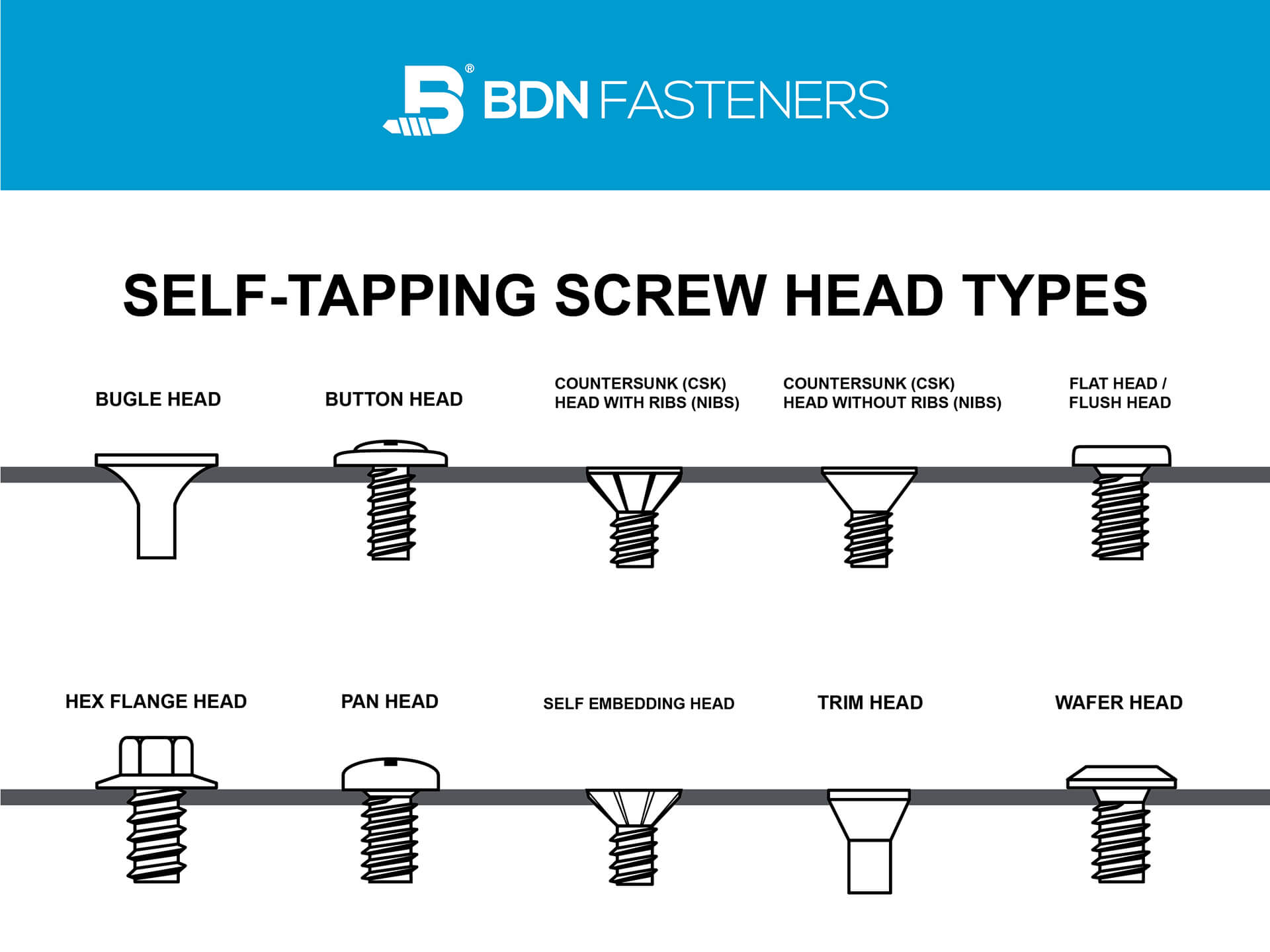

Choosing the Right Screw for Your Project: When embarking on a DIY or construction project, selecting the right screw for the job can make all the difference in the outcome of the project. One type of screw that is commonly used in a variety of applications is the self-tapping screw. Self-tapping screws are designed to tap their own hole as they are driven into the material, making them a convenient option for many projects. However, not all self-tapping screws are created equal, and it’s important to choose the right one for your specific application. Factors to Consider: When selecting a self-tapping screw, there are a few factors to consider to ensure that you choose the right one for your project. These factors include: 1. Material: The type of material you are fastening into will play a significant role in selecting the right self-tapping screw. Different materials require different thread types and lengths to ensure a secure hold. 2. Screw Size: The size of the screw is also important to consider. Using a screw that is too small or too large can lead to a weak hold or damage to the material. 3. Head Type: Self-tapping screws come in a variety of head types, including flat head, pan head, and round head. The head type you choose will depend on the specific application and aesthetic preferences. When to Use Self-Tapping Screws: Self-tapping screws are a great option for a variety of applications. They are particularly useful in situations where drilling a pilot hole is not possible or practical. Some common uses for self-tapping screws include: 1. Fastening metal to metal or metal to plastic 2. Joining thin sheets of metal or plastic 3. Assembling furniture or cabinetry 4. Installing drywall or other building materials In summary, when choosing a self-tapping screw, it’s important to consider factors such as material, screw size, and head type to ensure a secure and lasting hold. Self-tapping screws are a versatile option for a variety of applications and can save time and effort in projects where drilling a pilot hole is not possible.Maintenance And Troubleshooting

A self-tapping screw is a versatile fastener commonly used in various applications, including metal, wood, and plastic. To ensure the efficiency and longevity of self-tapping screws, it’s crucial to address maintenance and troubleshooting aspects. This involves preventing and managing issues, as well as replacing damaged screws when necessary.

Preventing And Managing Issues

Proper installation is essential to prevent issues with self-tapping screws. Ensure that the material being fastened is suitable for self-tapping screws, and use the appropriate screw size and type for the application. Avoid over-tightening, as it can strip the threads or damage the material. Additionally, regularly inspect the screws for signs of corrosion, wear, or loosening.

Replacing Damaged Screws

When encountering damaged or worn self-tapping screws, it’s crucial to promptly replace them to maintain the structural integrity of the assembly. Start by carefully removing the damaged screw using the appropriate tools to avoid causing further damage to the material. Select a replacement screw of the correct size and type, ensuring it matches the specifications of the original screw.

Credit: www.amazon.com

Frequently Asked Questions

What Is The Purpose Of Self-tapping Screws?

Self-tapping screws are used to create their own hole when driven into materials like metal, wood, or plastic.

What Is The Difference Between A Self-tapping Screw And A Normal Screw?

A self-tapping screw can create its own hole, while a normal screw requires a pre-drilled hole.

What Is The Disadvantage Of Self-tapping Screws?

The main disadvantage of self-tapping screws is that they require drilling of a pilot hole, which can cause thermal damage and potentially lead to infection, loosening of hardware, and nonunion. Additionally, self-tapping screws cannot drill through metal and are only suitable for use in relatively soft materials or sheet materials, excluding wood screws.

Do You Need A Drill For Self-tapping Screws?

Yes, you need a drill for self-tapping screws to create a pilot hole before driving them in.

Conclusion

Self-tapping screws are versatile fasteners that can create their own threads. They are ideal for use in metal, wood, and plastic materials. With their sharp points and threads, they efficiently cut through various mediums without the need for pre-drilling. Explore the benefits of self-tapping screws for your projects.